Measuring laboratory

Lumel Alucast is a certificated supplier in the scope of ISO 9001:2015 and standard IATF 16949: 2016. We also take care to ensure

the compliance of our castings with requirements concerning their properties and impact to environment, what is confirmed by certificate of compliance with the requirements of ISO 14001:2015.

At Lumel Alucast main goal is customer’s satisfaction, so our top priority is ensuring the quality for pressure castings.

We strive to continuous improvement of our processes according with the assumption of the Quality Management System.

The result of a pro-quality approach is assurance, that customer requirements are met at every stage of production, from input material checking to finished products. At our plant we aspire to create the quality, not only control the quality of our castings – that is why continuous improvement process is very important aspect for us.

As Edward Deming used to say: “Quality is a way of thinking that makes us use and constantly look for the best solutions”

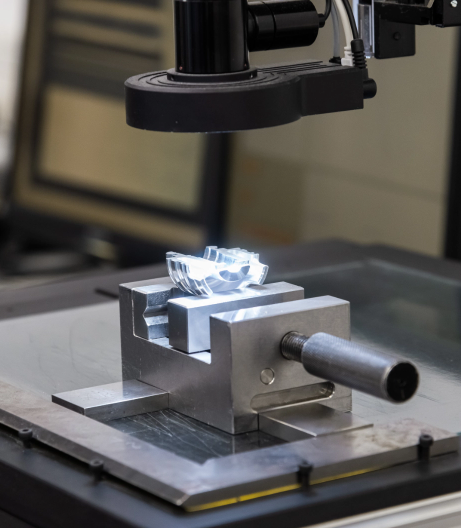

3D geometrical

measurements

The relatively young but dynamically developing field of measuring geometric quantities has also found application in our laboratory. Using coordinate measuring machines we perform unit measurements as well as for serial production. Thanks to integration with CAD / CAM systems, we are also able

to perform computer analysis for irregular surfaces.

To measure the functional geometry of the workpieces we use the fast, simple and economical MarSurf XC-20 contour measuring system that meets the high accuracy requirements. For this purpose, we use, among others Wenzel system with MPEE = 2.6μm + (L / 450mm) μm – in the measuring range 800/1000/700 (X / Y / Z). We are able to perform more precise measurements of shape, runout and direction deviations using the MarForm MMQ-400 device,

in the range of 280 / 900mm (X / Z), with a maximum allowable measurement error of 0.04μm.

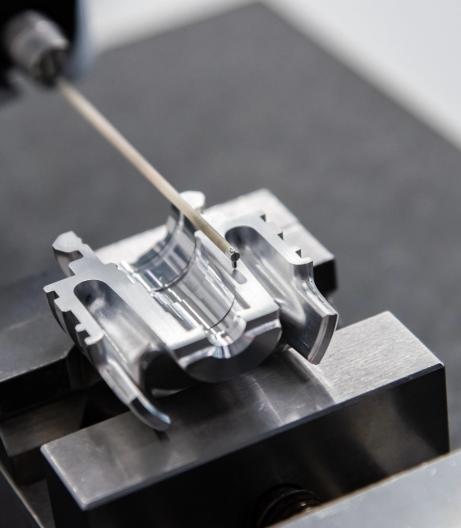

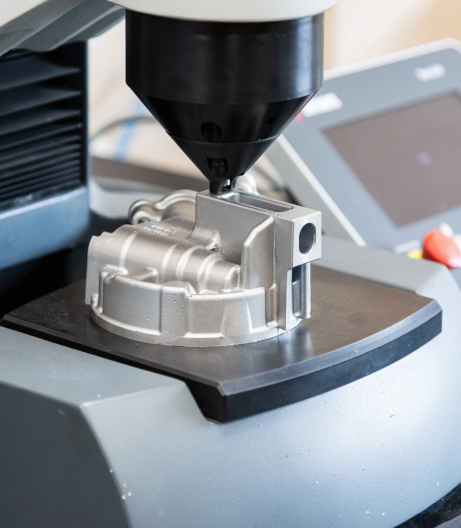

Measurements of geometric

value with optical method

The Baty Venture 3030 optical measuring system with CNC mode is not only

a perfect complement to coordinate measuring machines, but also a universal system used by us for the analysis of surface defects.

Due to the use of the Struers Discotom-100 + Labopol-30 system, there are also internal defects in pressure castings.

The available measuring range of the machine is 300/300 / 150mm (X / Y / Z) with measurement uncertainty U95 = +/- (2+ (4.5 * L / 1000)) µm.

Supervision over control

and measurement equipment

One of the main tasks of our laboratory is to supervise the control

and measurement equipment. In this regard, we supervise ring gauges, piston gauges, thread gauges, two-point and three-point bore gauges, calipers, micrometers, dial gauges and digital, altimeters and depth gauges.

For this purpose, we use, among others, vertical and horizontal ABBE length gauges. We also have a set of gauge blocks in the highest accuracy class.

Measurements

of geometrical

structure of surface

In our laboratory we assess the surface geometry structure using the profile method. For this purpose we use the MarSurf XR-1 system. It is a flexible system with a wide range of styli, with which we are able to control

80 parameters for R, P, W profiles according to the current ISO / JIS

or MOTIF (ISO 12085) standards.

Hardness

measurements

To test such an important feature as the hardness of the material we use

the system of the leader in the production of this type of equipment by Struers. The tests are carried out using the Rockwell HRC / HRB method

in the complete load range of 9.8N to 2450N.

With this system, it is possible to measure the hardness of plastics, carbon materials and to measure indirect HVD / HBD methods.

Chemical composition

check and analysis

In order to precisely analyze the chemical composition, we use a spark spectrometer, which ensures low detection thresholds of light elements

in aluminum alloys, copper and steels.

Thickness

measurement

of galvanic coatings

We perform coating thickness measurements during the NDT test.

For this purpose we use LEPTOSKOP® 2041 from KARL DEUTSCH.

We carry out tests on Fe / NFe substrates (0 – 500 µm) with a measurement uncertainty of 1% ± 1 µm for coatings <100 µm and 1..3% ± 1 µm

for coatings> 100 µm.

X-ray

examinations

Our equipment includes the universal YXLON MU2000 X-ray system.

The system is characterized by speed and precision in operation, which makes it ideal for serial and random testing of castings, welded joints, composites

and many other products.

Maximum allowable dimensions of the tested object: diameter 400 mm,

height 900 mm, weight 60 kg. Maximum wall thickness: aluminum 200 mm, steel 35 mm, cast iron 20 mm.

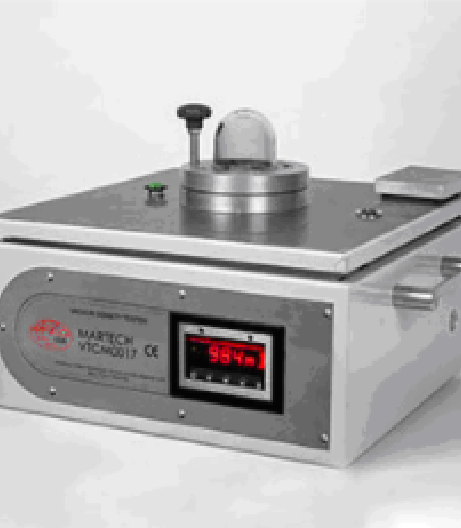

Alloy density

index analysis

The density index is a parameter that determines the purity of the molten metal.

For pressure die-casting of aluminum alloys, the permissible value

of the density index is 0-3%. In order to test the alloy density index

after the melting and degassing processes, we use the Aluminum Density Tester Martech-VCTM 0017, which allows us to make samples and calculate the obtained results using the NAGATA FATH 06S scale.

Contact

ul. Słubicka 1

65-127 Zielona Góra | Poland

(+48 68) 45 75 100

lumel@lumel.com.pl

Lumel Alucast Sp. z o.o.

Bank account: ING Bank Śląski S.A.

PL16 1050 1520 1000 0023 2840 8618 (PLN)

PL05 1050 1520 1000 0023 2840 8816 (EUR)

PL08 1050 1520 1000 0023 2840 9053 (USD)

SWIFT: Code INGBPLPW

Registered in District Court in Zielona Góra, VIII Economic Department

of Domestic Court Register under No. KRS 0000381491

NIP 527-265-14-70

Initial capital: 5 916 600 PLN

© 2024 | Copyright by LUMEL ALUCAST Sp. z o.o.